Unlocking Reliability and Cost Efficiency: Why U.S. Buyers Are Partnering with India for Custom Stamped and Sheet Metal Parts

In today’s competitive manufacturing environment, U.S. procurement professionals, OEMs, and supply chain managers are under pressure to deliver consistent quality, control costs, and meet production timelines. With increasing domestic challenges, many are exploring international sourcing. India is emerging as a top destination, offering a powerful combination of technical expertise, cost-effectiveness, and reliable manufacturing infrastructure.

At Dakshtools, we’ve seen this trend firsthand. As a trusted Indian manufacturer and exporter of precision metal fabricated components, we specialize in delivering custom sheet metal parts, metal stampings, and pressed components built to meet the high standards of our U.S. clients. Here’s why more American companies are turning to India—and to Dakshtools—as a strategic sourcing partner.

Why India Stands Out in Metal Fabrication

India’s emergence as a reliable sourcing hub for stamped and sheet metal components is fueled by several key factors:

1. Skilled Workforce & Engineering Expertise

India offers a large pool of experienced engineers and technicians who are well-versed in precision metalwork. Manufacturers regularly work with CAD/CAM tools, CNC machining, and quality systems to produce components like sheet metal chassis and brass architectural hardware with accuracy and repeatability.

2. Modern Manufacturing Infrastructure

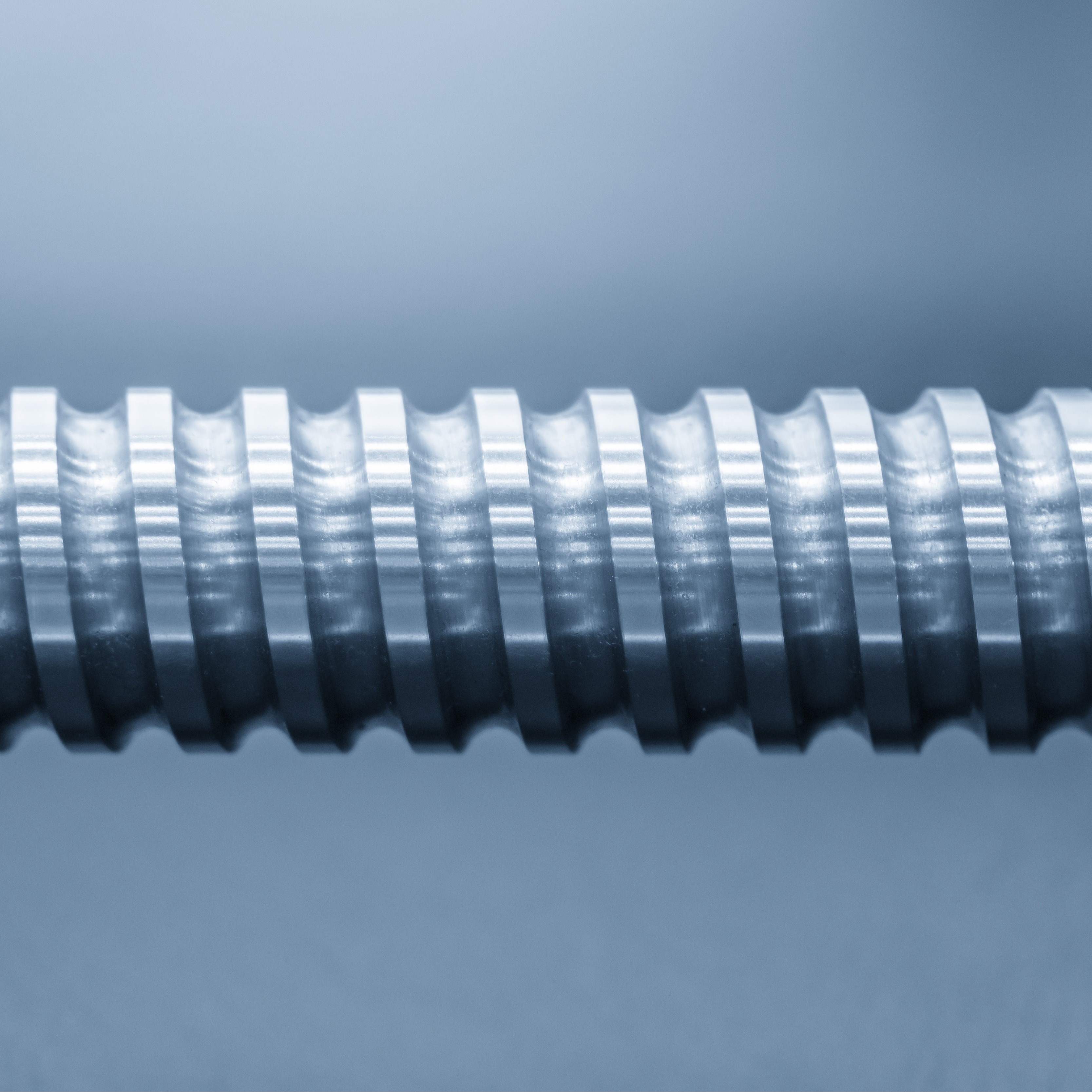

At Dakshtools, we’ve invested in advanced production technologies including laser cutting, CNC machining, progressive stamping presses, robotic welding, and powder coating. These capabilities enable us to manufacture high volumes of complex parts with tight tolerances, such as solar panel mounting structures, stainless steel brackets, and custom enclosures.

3. Competitive Pricing, High Quality

Indian manufacturers can offer substantial cost savings due to efficient labor and lean operations. The result: high-quality parts at globally competitive rates. Whether you need aluminum housings, carbon steel parts, or precision stamped components, India delivers strong value without cutting corners.

4. Global Standards & Export Experience

Export-ready Indian companies like Dakshtools understand the needs of U.S. clients. We’re ISO 9001-certified, adhere to RoHS and other compliance standards, and are experienced in international packaging, documentation, and shipping protocols.

Dakshtools: Your Partner in Precision

We support U.S. manufacturers across industries like automotive, solar, electronics, and architecture with end-to-end fabrication services:

Sheet Metal Fabrication

We handle all stages—from design and prototyping to cutting, bending, welding, and finishing. Our materials expertise includes mild steel, stainless steel, aluminum, copper, and brass.

Metal Stamping & Pressed Parts

Using high-tonnage presses and in-house tooling, we offer precision stamping ideal for automotive components, electrical enclosures, and fasteners, with tight tolerances and consistent results.

Custom Engineering Support

Our engineers collaborate closely with clients, helping optimize designs for functionality and manufacturability—whether it’s a custom bracket or a decorative brass piece.

Surface Finishes

We provide finishing options such as powder coating, anodizing, painting, and plating to enhance both performance and aesthetics.

Trusted by U.S. Companies

Our relationships with American businesses showcase our commitment to quality and reliability:

A U.S. solar energy firm sourced solar mounting structures from us to reduce costs and increase speed to market.

An automotive OEM relies on us for high-precision stamped parts that meet tight deadlines and quality specs.

Multiple architectural firms across the U.S. have chosen our brass hardware for premium residential and commercial installations.

Staying Ahead of Industry Trends

At Dakshtools, we’re committed to continuous improvement. We track trends such as lightweight material adoption, automation, and sustainability—investing in new technologies to offer innovative and eco-friendly solutions to our partners.

Discover the Dakshtools Advantage

If you're seeking a reliable partner for cost-effective, high-quality metal fabricated parts, Dakshtools is ready to deliver. We combine technical precision, responsive service, and export-ready capabilities—all with the flexibility and efficiency global businesses need.

Get Started Today:

Request a Quote – Send us your drawings and specs for a custom proposal

Explore Our Services – Visit our website for a full overview of capabilities

Let’s Talk – Reach out to discuss your project needs and timelines

👉 Visit www.dakshtools.com to learn more.

Dakshtools — Precision Fabrication. Global Reach. Local Commitment.

Keywords

quality systems

india stands

clients heres

unlocking reliability

full overview

quote send

exportready capabilitiesall

youre seeking

partners discover

ecofriendly solutions

offer innovative

track trends

continuous improvement

industry trends

premium residential

increase speed

reduce costs

inhouse tooling

hightonnage presses

stagesfrom design

compliance standards

lean operations

efficient labor

capabilities enable

powder coating

experienced engineers

large pool

american companies

trend firsthand

powerful combination

dakshtools advantage

dakshtools understand

custom bracket

tight tolerances

custom stamped

services visit

aesthetics trusted

high standards

cost efficiency

reliable partner

produce components

dakshtools weve

complex parts

brass hardware

dakshtools weve invested

meet tight deadlines

highprecision stamped parts

provide finishing options

advanced production technologies

brass architectural hardware

strategic sourcing partner

shipping protocols dakshtools

custom proposal explore

meet production timelines

timelines visit wwwdakshtoolscom

efficiency global businesses

american businesses showcase

engineers collaborate closely

manufacture high volumes

trusted indian manufacturer

sheet metal components

reliable sourcing hub

pressed components built

reliable manufacturing infrastructure

result highquality parts

sheet metal parts

started today request

automotive oem relies

cutting bending welding

automotive solar electronics

international packaging documentation

iso 9001certified adhere

globally competitive rates

sheet metal chassis

technical expertise costeffectiveness

top destination offering

increasing domestic challenges

supply chain managers

procurement professionals oems