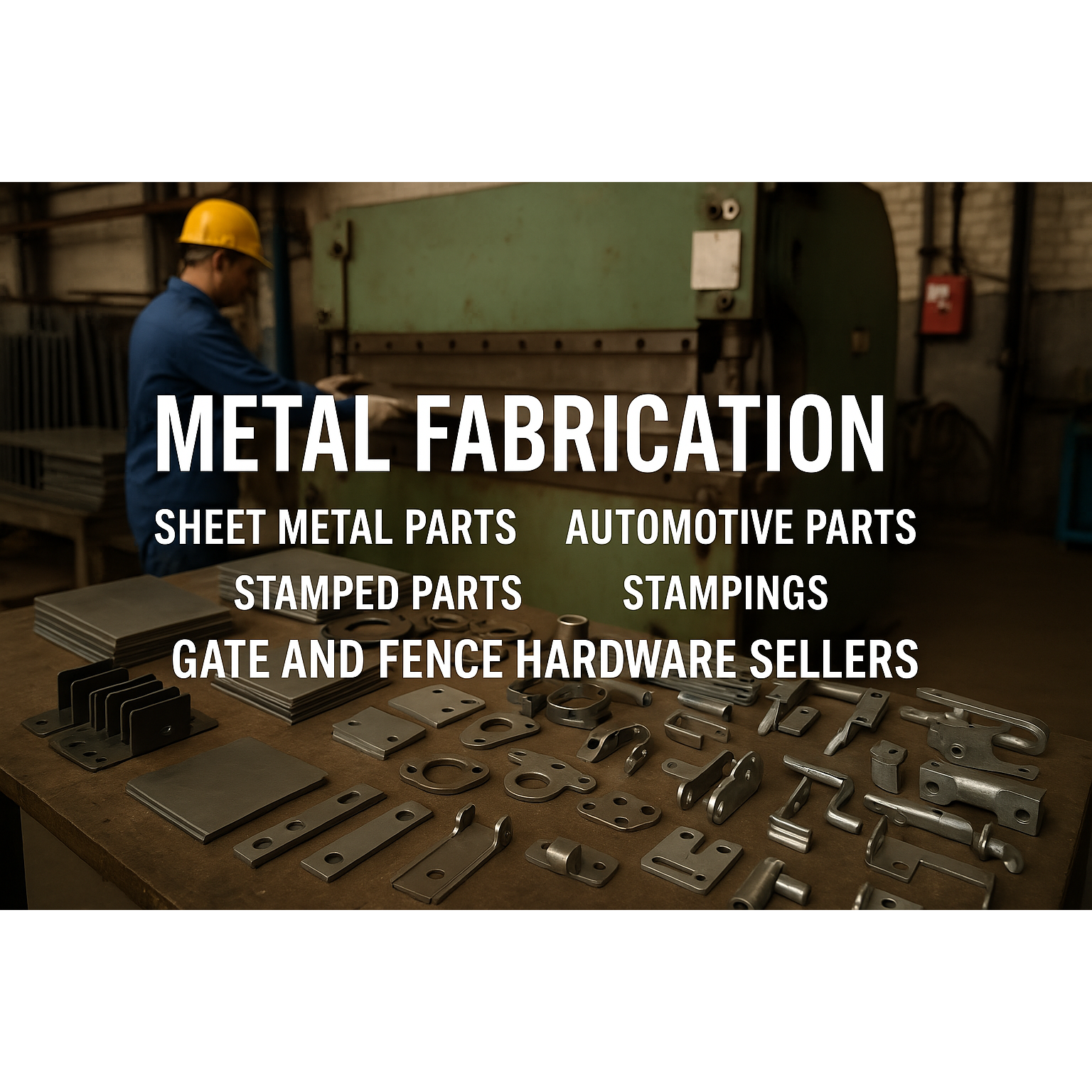

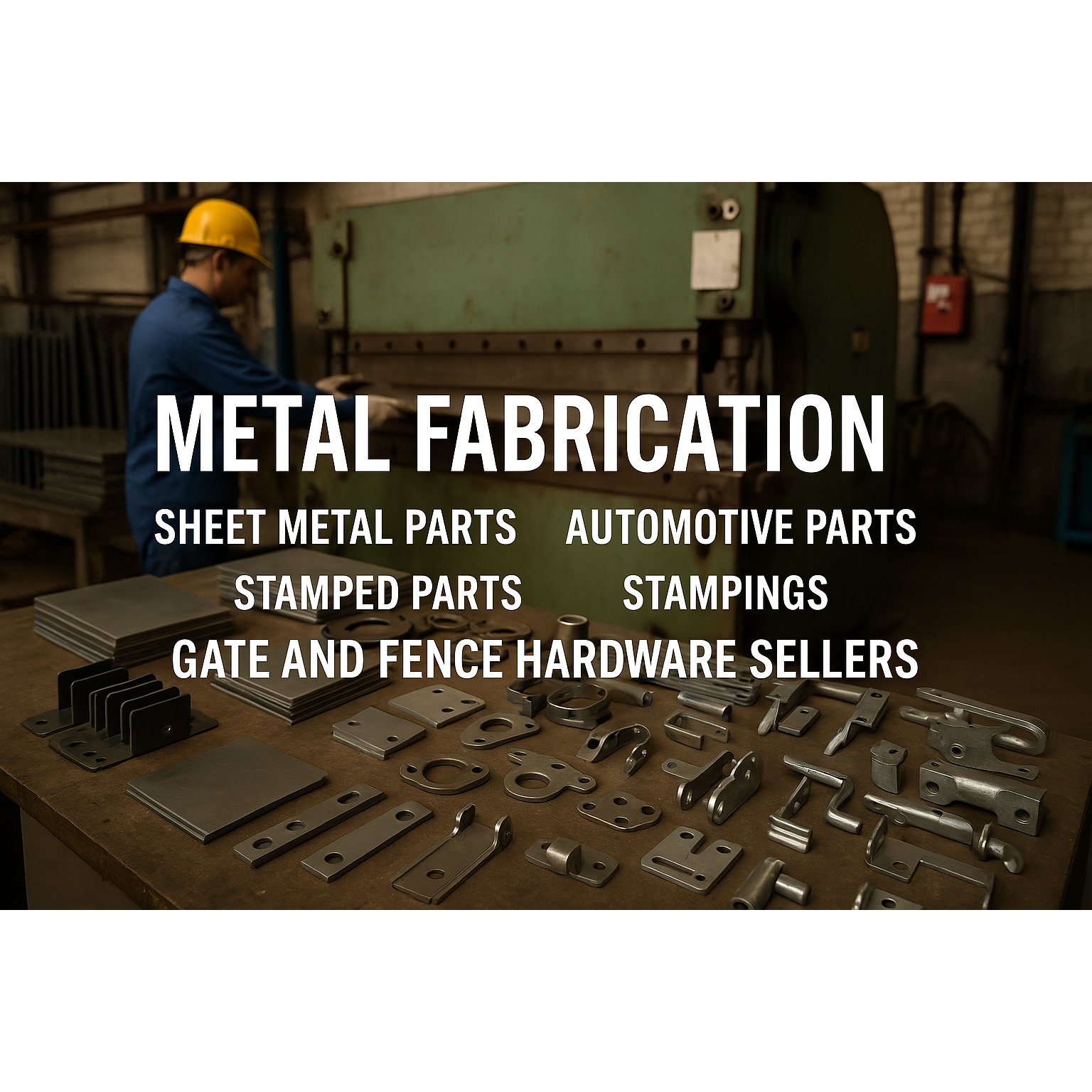

Stamping Parts Manufacturing in India: A Growing Hub for Precision Engineering

Introduction India has emerged as a leading global hub for stamping parts manufacturing, catering to various industries such as automotive, aerospace, electrical, and consumer goods. With its competitive labor costs, advanced technology adoption, and a strong supply chain, India is rapidly gaining recognition as a reliable destination for precision-engineered stamped components.

Why Choose Daksh Tools and India for Stamping Parts Manufacturing?

Cost-Effective Production: India offers competitive manufacturing costs due to affordable labor and raw materials, making it a preferred choice for global buyers.

Advanced Technology & Automation: Indian manufacturers leverage advanced stamping presses, CNC machines, and automation to ensure high-quality production.

Skilled Workforce: The country boasts a highly skilled workforce with expertise in precision engineering, die-making, and metal fabrication.

Strong Supply Chain: India has a well-established supply chain network, ensuring timely procurement of raw materials and efficient logistics support.

Government Initiatives: The ‘Make in India’ initiative and favorable policies have further boosted the manufacturing sector, encouraging investment and growth.

Types of Stamping Parts Manufactured in India

Automotive Stamping Parts: India is a key supplier of precision-engineered components for automobiles, including chassis parts, brackets, and connectors.

Electrical & Electronics Components: Stamped metal components for electrical appliances, connectors, and switchgear are widely produced.

Aerospace & Defense: High-precision stamping parts for aircraft, missiles, and defense equipment are manufactured with stringent quality controls.

Consumer Goods & Industrial Applications: Stamped parts for kitchen appliances, home appliances, and industrial equipment are also produced in large volumes.

Quality Standards & Certifications Indian stamping parts manufacturers adhere to international quality standards such as ISO 9001, IATF 16949 (for automotive), AS9100 (for aerospace), and other industry-specific certifications. This ensures that the products meet global standards for durability, precision, and safety.

The Future of Stamping Parts Manufacturing in India With continuous investments in technology, skill development, and infrastructure, India is poised to become a dominant player in the global stamping parts industry. The rise of electric vehicles (EVs), automation, and increased demand for precision components will further propel the growth of this sector.

For inquiries about custom stamping parts manufacturing, reach out to Daksh Tools for top-quality solutions tailored to your needs.

Keywords

infrastructure india

india initiative

growth types

increased demand

dominant player

continuous investments

industryspecific certifications

industrial equipment

defense equipment

aircraft missiles

key supplier

favorable policies

country boasts

preferred choice

affordable labor

reliable destination

consumer goods

durability precision

automotive as9100

growing hub

precision components

precisionengineered components

daksh tools

raw materials

automotive aerospace electrical

precisionengineered stamped components

stamping parts manufactured

raw materials making

choose daksh tools

precision engineering diemaking

leading global hub

topquality solutions tailored

technology skill development

international quality standards

electrical appliances connectors

chassis parts brackets

highly skilled workforce

rapidly gaining recognition

stamping parts manufacturing