## Leading Metal Stamping Parts Manufacturers in India

India has emerged as a significant hub for **metal stamping parts manufacturers**, offering a compelling combination of manufacturing capabilities, skilled labor, and cost-effectiveness. These manufacturers cater to a wide range of industries, producing everything from intricate electronic components to robust **automotive metal stamping India** parts and durable **industrial equipment metal parts exporter** components.

Here's a glimpse into what makes Indian manufacturers a strong choice for your metal stamping needs:

**Key Strengths of Metal Stamping Manufacturers in India:**

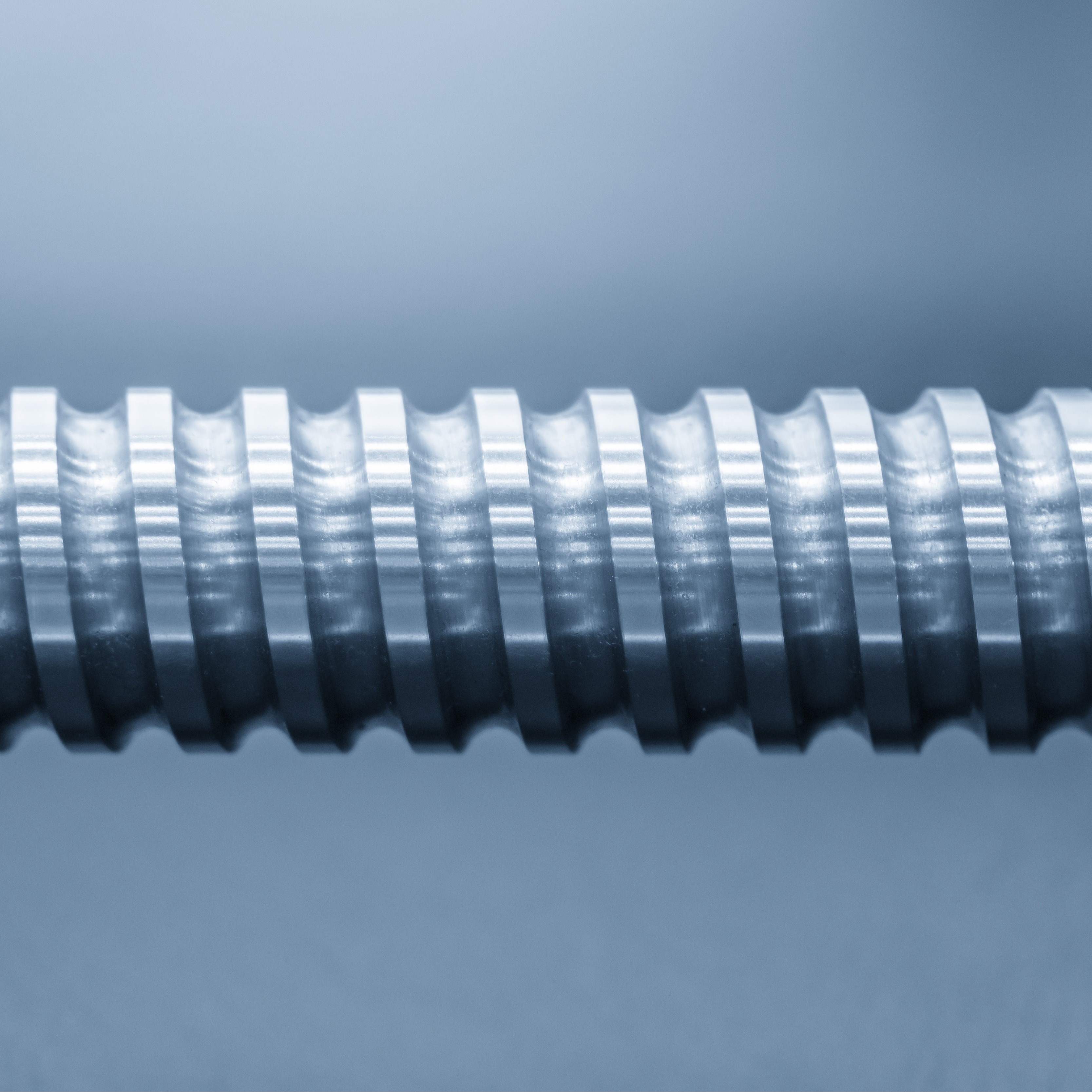

* **Diverse Capabilities:** Indian manufacturers offer a wide spectrum of stamping processes, including **progressive die stamping parts supplier** capabilities for high-volume complex parts, **deep drawn stamping parts** for cupped or cylindrical shapes, and various other techniques like blanking, piercing, bending (**sheet metal bending services**), and forming.

* **Material Expertise:** They work with a comprehensive range of materials, including various grades of steel (including **cold rolled steel components**, **carbon steel metal fabrication**, and **galvanized steel sheet metal parts**), aluminum (**aluminum fabricated parts supplier**), stainless steel (**stainless steel stamping parts**), brass, copper, and more.

* **Precision and Quality:** Many manufacturers focus on **precision metal stamping**, utilizing advanced machinery and adhering to stringent quality control measures. Achieving certifications like **ISO certified metal parts manufacturer India** is common, ensuring high standards.

* **Cost-Effectiveness:** India offers a competitive edge in terms of manufacturing costs, making it an attractive option for **low-cost country sourcing metal parts** without compromising on quality.

* **Customization:** Most manufacturers specialize in **custom metal fabrication supplier** services, capable of producing parts to exact specifications and drawings provided by the client. They can act as reliable **OEM metal parts manufacturer** partners.

* **Global Export Capability:** Many Indian companies are experienced **steel parts exporter India** and **metal press parts exporter**, equipped to handle international logistics and ensure timely delivery, including **customs-cleared metal parts USA**.

**Notable Metal Stamping Processes Offered:**

* **Progressive Die Stamping:** Ideal for high-volume production of complex parts, using a series of dies in a single press.

* **Deep Draw Stamping:** Used to create cup-like or hollow shapes from sheet metal.

* **Fine Blanking:** A precision stamping process that produces parts with very smooth, clean edges and tight tolerances.

* **High-Speed Stamping:** Optimized for rapid production of large quantities of parts.

**Applications Across Industries:**

**Metal stamping parts** from India find applications in numerous sectors, including:

* **Automotive:** Producing a wide array of components from body panels to brackets (**automotive metal stamping India**).

* **Electronics:** Manufacturing intricate connectors, housings, and shielding components.

* **Appliances:** Creating parts for white goods like refrigerators, washing machines, and ovens.

* **Industrial Equipment:** Producing robust components for machinery and equipment (**industrial equipment metal parts exporter**).

* **HVAC:** Manufacturing components for heating, ventilation, and air conditioning systems (**HVAC sheet metal parts supplier**).

* **Agriculture:** Supplying components for agricultural machinery (**agriculture machinery metal components**).

* **Electrical:** Producing enclosures and other electrical hardware (**electrical enclosure sheet metal fabrication**).

**Choosing a Metal Stamping Partner in India:**

When selecting a **metal parts supplier overseas** in India for your **metal stamping parts supplier** needs, consider the following:

* **Experience and Expertise:** Look for manufacturers with a proven track record and experience in your specific industry and the types of parts you require.

* **Manufacturing Capabilities:** Ensure they have the necessary equipment and processes to meet your volume, complexity, and material requirements.

* **Quality Standards and Certifications:** Check for ISO certifications and their quality control processes.

* **Communication and Project Management:** Effective communication and project management are crucial for successful offshore manufacturing partnerships.

* **Logistics and Shipping:** Inquire about their export capabilities and experience with shipping to the U.S., including customs clearance.

* **Cost Structure:** Understand their pricing model and ensure it aligns with your budget.

By carefully evaluating potential partners, U.S. businesses can leverage the strengths of **metal stamping parts manufacturers in India** to achieve cost savings, maintain high quality, and build a resilient supply chain.

Keywords

india india

shipping inquire

quality customization

key strengths

produces parts

complex parts

producing parts

pricing model

export capabilities

project management

iso certifications

certifications check

volume complexity

specific industry

heating ventilation

white goods

body panels

wide array

automotive producing

numerous sectors

large quantities

rapid production

hollow shapes

create cuplike

highvolume production

drawings provided

exact specifications

attractive option

competitive edge

comprehensive range

cylindrical shapes

wide spectrum

strong choice

industries producing

wide range

compelling combination

significant hub

stamping processes

manufacturers specialize

manufacturers focus

manufacturers cater

parts applications

indian companies

metal stamping

india find applications

metal stamping manufacturers

precision stamping process

makes indian manufacturers

ensure timely delivery

forming material expertise

intricate electronic components

metal stamping partner

resilient supply chain

proven track record

refrigerators washing machines

smooth clean edges

handle international logistics

manufacturing costs making