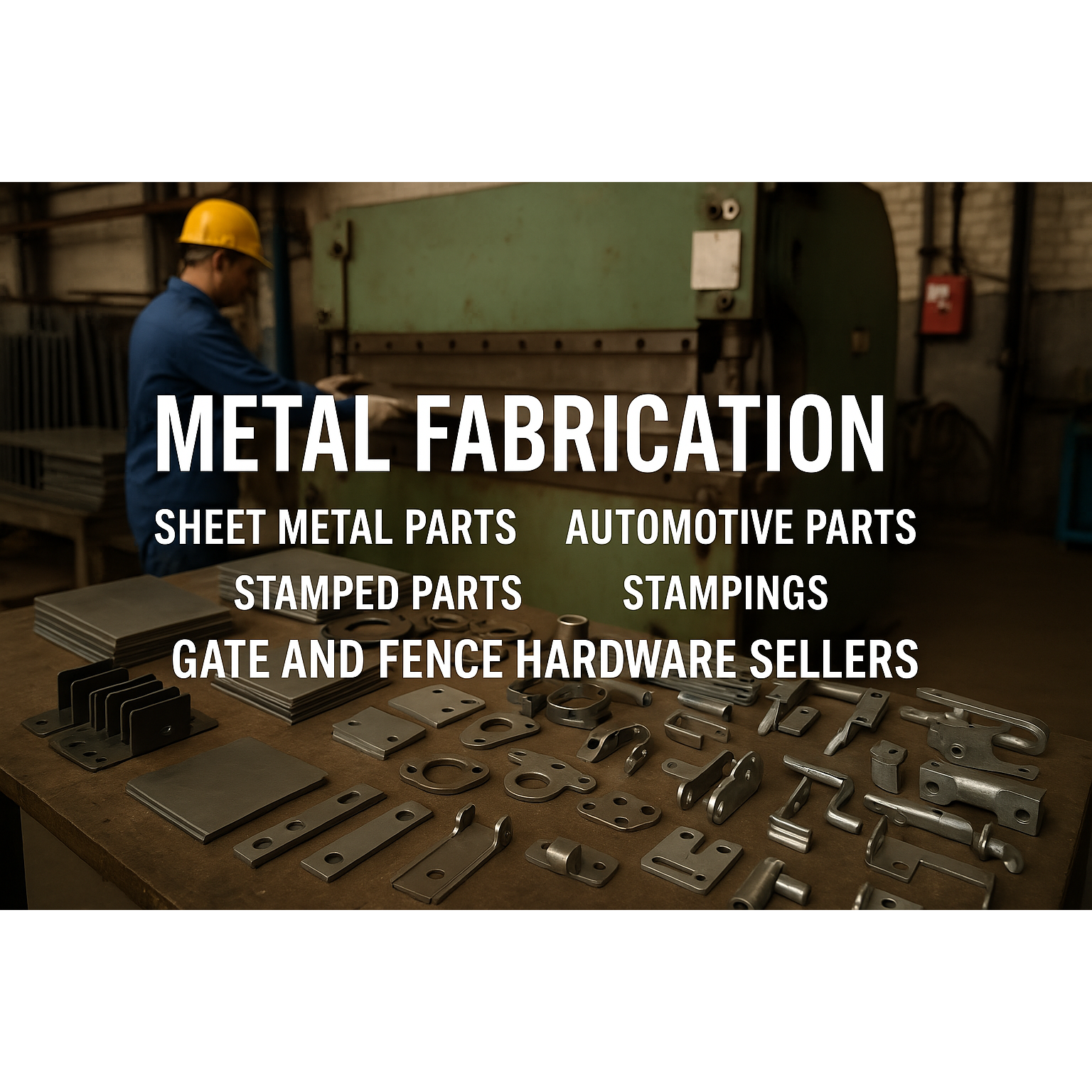

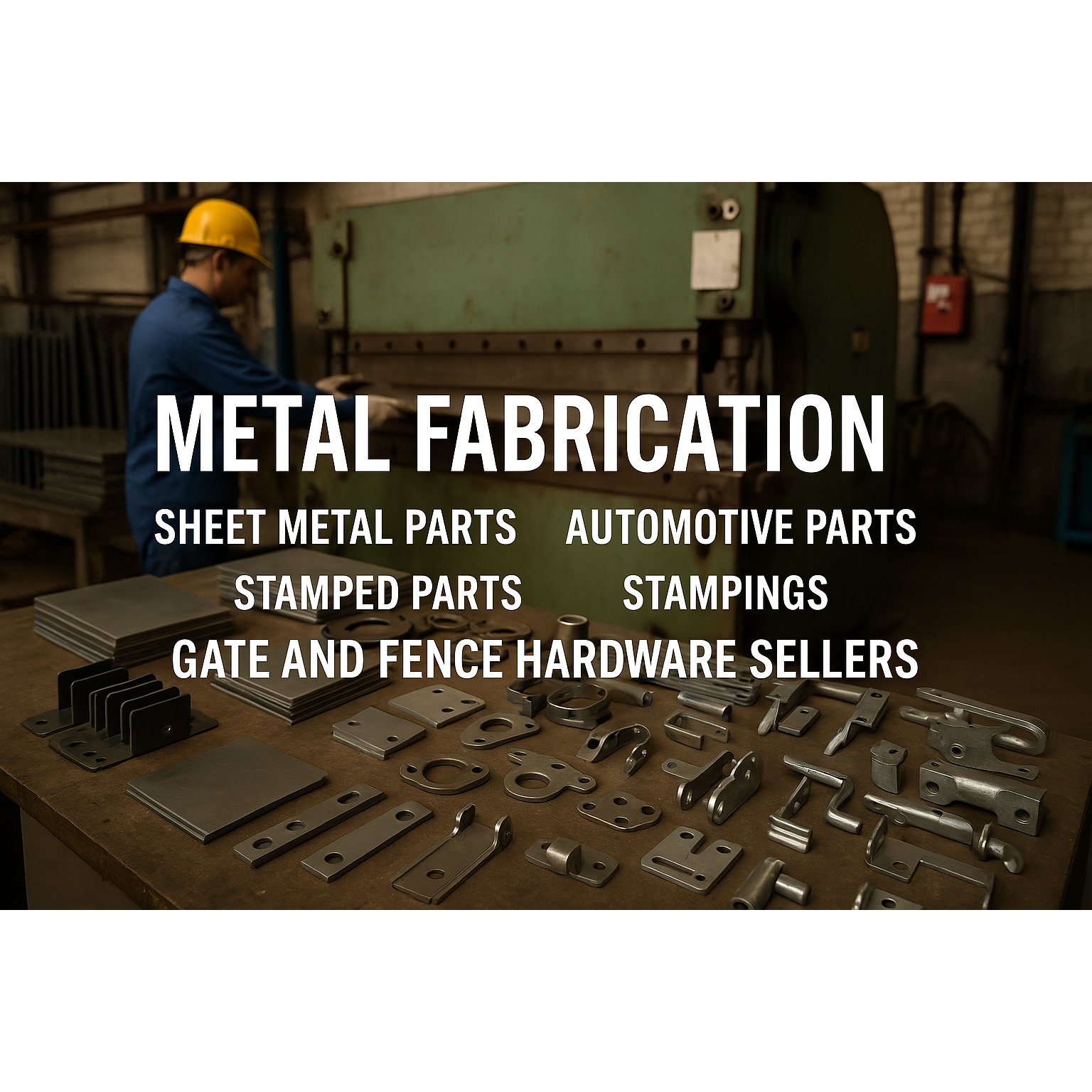

CUSTOM SHEET METAL FABRICATION | SHEET METAL FABRICATORS IN INDIA: Sheet metal fabrication is a complicated procedure that involves bending as well as shaping processes of different sheet metal techniques. It can be used to seal all kinds of obscure and hollow shapes/sections. Equipment used for this process range from handy tools to highly gift-operated automatic machinery. To carry out sheet metal fabrication services, you need an expert. At Daksh Tools, we take of all your needs and deliver services right on time.

With a team of skilled technicians and technologically advanced tools, at Lancerfab Tech we always believe in giving you customized services. As per your requirement, we can deliver the desired part.

What is Sheet Metal Fabrication?

It is a manufacturing process that can shape any piece of sheet metal – we give a desired shape through material removal technique or material deformation technique. Only trained sheet metal fabricators can perform these jobs efficiently. Sheet metal is basically the work piece in this process, or the raw material. Sheet metal stock can be found in various materials, such as:

Aluminium

Stainless steel

Brass

Steel

Bronze

Copper

Tin

Magnesium

Zinc

Titanium

Nickel

Being ad advanced and experienced sheet metal fabrication company, we believe in educating our customers so that they can make a customized choice.

Benefits of Sheet Metal Fabrication

Sheet metal fabrication ensures that any piece of sheet metal can be easily stretched, bent, and cut into any possible shape. There are two stages of sheet metal fabrication process:

Material removal is another process included in sheet metal fabrication services that can create cut-outs and holes in any type of 2D shape.

Deformation process that can bend a sheet innumerable times, to various angles, or event stretch a sheet and create complicated contours.

Sheet metal part sizes can range from small bracket or washer like shape to a midsized enclosure used in home appliances. It may also be used for airplane wings. As the leading sheet metal fabricators in India, we have served various industries like automotive, aircraft, consumer products, construction, furniture, and HVAC. Sheet metal fabrication in India is known by our name, Daksh Tools.

Categories of Sheet Metal Fabrication

Sheet metal fabrication in India is divided into 2 processes and categories:

• Forming: Forming process is the method in which an applied force leads to deformation of a plastic material, but it doesn’t fail. These processes are mainly used to stretch or bend any sheet into a particular shape. Forming involves bending, roll forming, spinning, deep drawing and stretch forming. At Daksh Tools, we offer all these sheet metal fabrication work.

• Cutting: Cutting process is a method in which the applied force leads to the failure of a material – the material fails and separates, and there’s no choice but to remove or cut it. Cutting process is generally performed with great shearing force applied to separate materials. As such, this process is also called shearing. It includes methods like shearing, blanking, punching, laser beam cutting, plasma cutting and water jet cutting.

At Daksh Tools, we take the responsibility as the most reliable sheet metal fabricating company, to offer genuine quality and reliable services.

Keywords

Zinc

type

gift

jobs

HVAC

team

time

name

kinds

needs

INDIA

event

holes

method

expert

washer

Nickel

shaping

obscure

failure

bending

2D shape

Benefits

Titanium

cut-outs

aircraft

blanking

punching

Aluminium

customers

Equipment

furniture

processes

work piece

automotive

Categories

two stages

requirement

Daksh Tools

handy tools

raw material

desired part

construction

deep drawing

small bracket

possible shape

responsibility

various angles

Lancerfab Tech

advanced tools

plasma cutting

airplane wings

Forming process

Cutting process

genuine quality

home appliances

particular shape

plastic material

sheet innumerable

water jet cutting

various materials

reliable services

customized choice

consumer products

Sheet metal stock

separate materials

laser beam cutting

various industries

midsized enclosure

skilled technicians

customized services

Deformation process

Copper

Tin

Magnesium

great shearing force

complicated contours

complicated procedure

manufacturing process

hollow shapes/sections

Sheet metal part sizes

material removal technique

sheet metal fabrication work

operated automatic machinery

material deformation technique

CUSTOM SHEET METAL FABRICATION

leading sheet metal fabricators

sheet metal fabrication process

sheet metal fabrication services

different sheet metal techniques

Stainless steel

Brass

Steel

Bronze

reliable sheet metal fabricating company

experienced sheet metal fabrication company